I love a sporting event in a big stadium—the noise, camaraderie and the sense of belonging to your team as you bond with other fans over the participants you are cheering on. But have you ever thought about how the stadium got built? And more critically, have you ever considered how it got built on time and on a budget for the start of a season or a time critical event like the Olympics?

As Bath Rugby Club found out in 2021—having to get a restrictive covenant ruled ineffective by the Court of Appeal so that it could progress its new stadium development—you need to get the basics right and establish whether you can legally do all that you want at the site of your proposed stadium before you even start construction and planning.

Then, you need to adopt this mantra: “Plan, plan, and plan again, and build in extra contingency.”

Below, I set out matters that are, in my experience, unique to getting a stadium built on time, on budget, with satisfactory quality and so it generates revenue:

- The views of stakeholders (e.g. athletes, local residents, governing bodies, disability groups, emergency services, health and safety, hospitality, fans, tv and media, match day or event operations, non-match day revenue generation, future maintenance operations) must be canvassed early to decide what of their views and requirements can or need to be incorporated in the proposed development.

- In respect of stakeholders, do not underestimate the impact of television, media and smart technology on your stadium. Facilities must be appropriate and future-proofed to accommodate television, media and smart technology (e.g. smart turnstiles and hospitality/food and beverage offerings and equipment) with more than adequate data connectivity.

- You must absolutely adhere to the requirements of the sports’ governing body for the stadium’s proposed use(s), especially regarding the playing surface and arena configuration requirements or player’s facilities (e.g. the construction materials and measurements of a running track or dimensions of a football pitch and dressing rooms.)

- Normal expectations for competitive tendering do not apply. For example, you go out to five main contractors for competitive build costs. For certain specialised packages of the build (e.g. seating), all five potential main contractors come back with seating prices from the same two seating subcontractors, due to a limited supply pool. So how do you get competitive and transparent pricing? You need transparency in the tender process to understand what makes up the pricing of the proposed main contractors’ packages. You may even need to obtain and pass on the results of your own investigations for bespoke packages to proposed main contractors or adopt a procurement approach, which is more akin to management contracting.

- Very large bespoke packages only available from limited suppliers often need a long lead time depending on other stadia being constructed in your region/continent at any given time. The procurement of the seating package is paramount, and must be given early consideration and priority, as should complex M&E elements.

- The traditional legal tool to try and get any construction project delivered on time is liquidated damages—a pre-agreed daily/weekly amount to be paid to the employer by the contractor for late completion of the construction project. However, in my experience on a mission critical stadium construction project (e.g. the London Stadium for the 2012 Olympics), no amount of accrued daily/weekly liquidated damages—however large—is going to compensate for the stadium not being ready for its planned event. The reputational damage to the employer, governing body and contractor, plus the costs of moving an event to another stadium, does not bear thinking about (e.g. moving TV, media, officials, competitors, training grounds and accommodation to an alternative existing venue). So creative thinking needs to be brought to bear on this issue. For example, you may not engage the cheapest main contractor on price, but the one with the largest reputation to protect and who demonstrates in the tender process the serious steps that it will take to protect its business reputation whatever.

- Stadium construction must be subject to the tightest of regular programme management, an understanding of what is on the critical path at all times, accurate, truthful, and honest information that flows from the contractor to the employer and its professional consultants and vice versa, and quick, straightforward dispute escalation and resolution processes. The project culture must be open and collaborative in actions as well as words, and be backed up with adequate legal drafting in contractual documents if any party decides to deviate from that path. All team members should understand schedules and deadlines before construction begins.

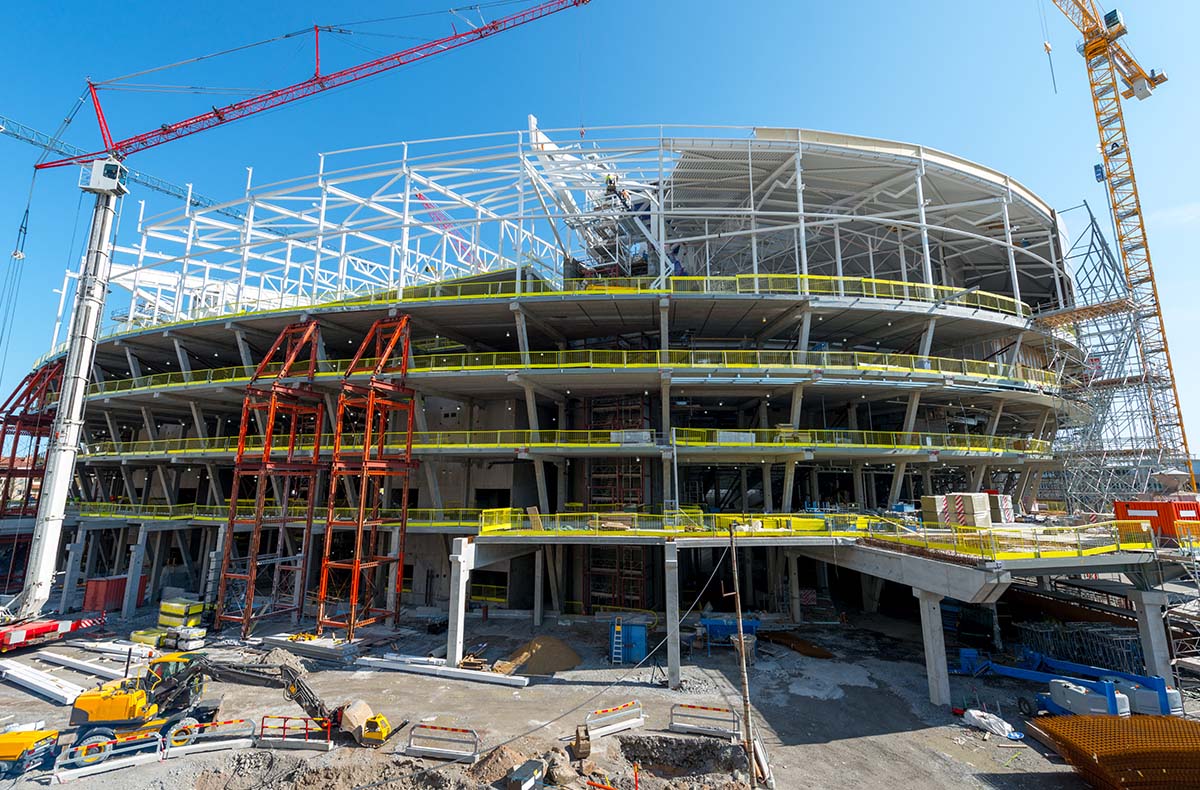

The state of the art Tottenham Hotspur Stadium, which opened late in April 2019 at a reported cost of circa £1billion, shows how far stadium construction has progressed and the trials and tribulations faced in the process. It’s a multi-purpose stadium with a seating capacity of 62,850, featuring the world’s first dividing retractable football pitch, which reveals a synthetic turf field underneath for NFL games in London, as well as facilities for concerts and other events, including smart tech such as the revolutionary bottom of the beer glass filling in Europe’s longest bar (65 metres).

Next time you are cheering your team on in their stadium, look around and take a minute to think about the work, and more importantly, the planning that got you sitting there. It will make the experience all the sweeter.